Find the Best Deals on Industrial Coffee Grinder Options Now

Find the Best Deals on Industrial Coffee Grinder Options Now

Blog Article

Top Attributes to Look for in an Industrial Coffee Mill

When examining an industrial coffee mill, it is vital to determine crucial attributes that impact both efficiency and durability. Consistency in grind dimension is essential for ideal extraction, while flexible grinding rate allows for a balance in between performance and quality.

Grind Size Consistency

While numerous factors can affect the top quality of made coffee, grind size uniformity remains extremely important in attaining optimal extraction. The uniformity of coffee premises straight impacts the developing process, as irregular particle sizes can cause over-extraction or under-extraction. This inconsistency results in imbalanced tastes, where specific notes may be overpowering while others are muted.

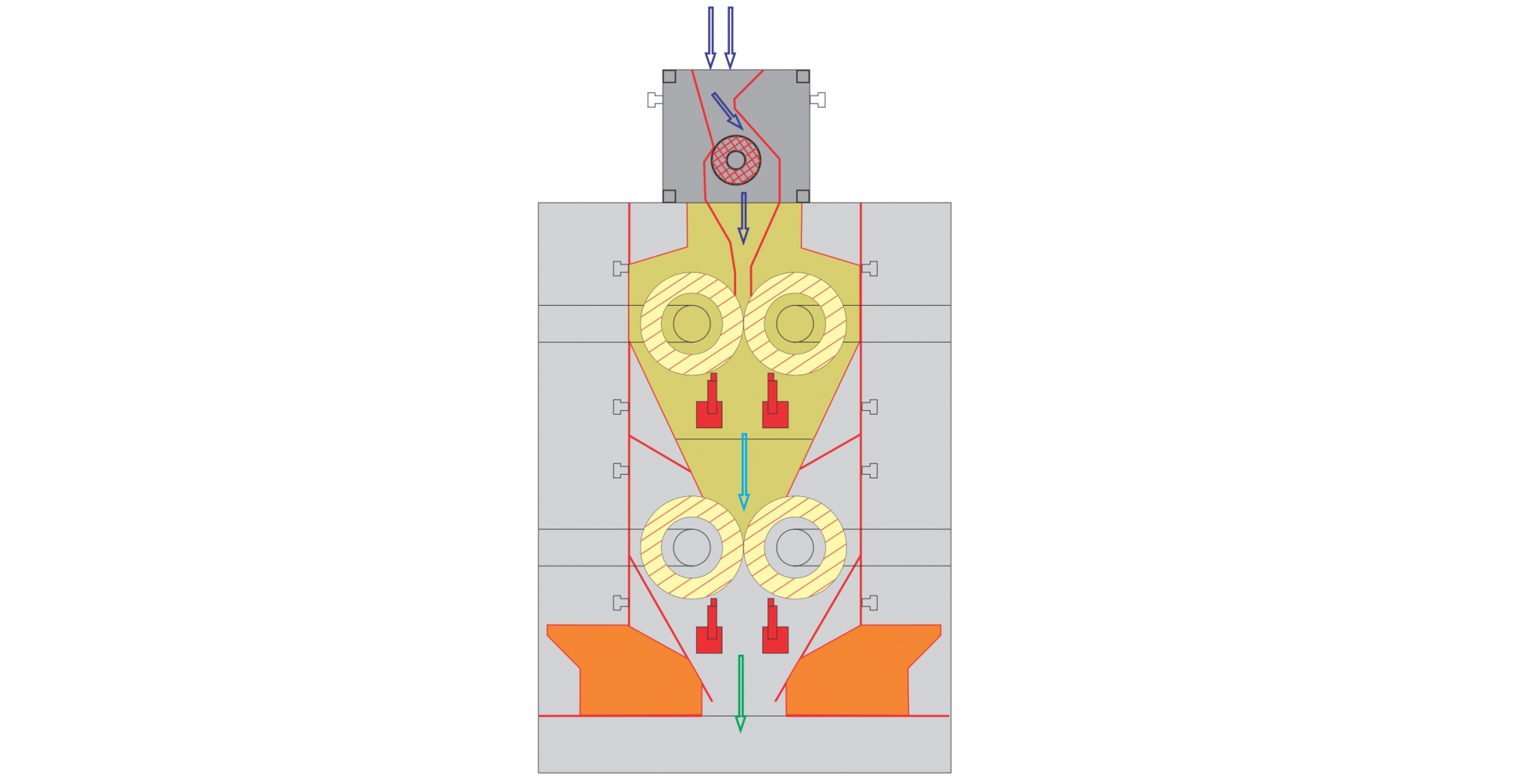

Industrial coffee grinders are developed to supply a high level of accuracy, commonly using burr grinding mechanisms to ensure an uniform work size. Unlike blade grinders, which can create a mix of penalty and rugged bits, burr mills crush the beans in between two surface areas, permitting far better control over grind size. This uniformity is critical across various brewing approaches, whether coffee, French press, or pour-over, as each strategy calls for details grind dimensions for ideal flavor removal.

In addition, consistency in work size adds to the general efficiency of the developing procedure. A consistent work permits also water circulation, minimizing the risk of channeling and boosting removal performance. In summary, buying an industrial coffee grinder with an emphasis on grind size uniformity is necessary for achieving high-grade coffee with preferable flavor accounts.

Grinding Rate

Grinding speed plays a vital duty in the total performance of commercial coffee grinders, straight affecting both the quality of the grind and the efficiency of the procedure. Industrial Coffee Grinder. Greater grinding speeds can considerably boost the throughput, making it feasible to process bigger amounts of coffee beans in a shorter timespan. This is specifically important for businesses that depend on high-volume production, such as coffee roasteries and coffee shops

However, while rate is important, it is similarly vital to stabilize it with the quality of the work. Excessively high grinding rates can produce warm, which may detrimentally influence the taste account of the coffee by causing the beans to lose vital oils and scents. For that reason, a grinder that offers flexible rate setups can offer ideal flexibility, allowing operators to tailor the grinding procedure according to specific needs.

In addition, the grinding speed ought to correspond to guarantee harmony in the work dimension, further adding to the overall taste and developing quality of the coffee. In recap, examining grinding speed is critical for selecting a commercial coffee mill that fulfills both performance and top quality needs.

Build Top Quality and Longevity

The efficiency of an industrial coffee grinder is not entirely figured out by its grinding rate; construct quality and resilience are just as vital aspects that influence lasting efficiency and integrity. A well-constructed grinder will hold up against the rigors of daily use, making it an audio financial investment for any industrial procedure.

Sturdiness additionally encompasses the grinder's motor and internal mechanisms. Industrial coffee mills need to be outfitted with heavy-duty electric motors with the ability of maintaining extended procedure without overheating. Durable burrs are necessary, as they directly impact the quality of the grind and add to the total long life of the machine.

Simplicity of Usage and Maintenance

Constantly focusing on ease of use and upkeep can considerably enhance the operational effectiveness of a commercial coffee grinder. User-friendly features such as user-friendly controls and clear labeling are necessary for reducing downtime and ensuring that operators can rapidly adjust to the equipment. An ergonomic style, consisting of height-adjustable hoppers and accessible grinding chambers, allows for comfortable procedure and assists in the loading and dumping of coffee beans.

Furthermore, convenience of maintenance is crucial for extending the lifespan of the mill. Devices with removable components and elements developed for fast cleansing can enhance upkeep jobs, lowering the time invested in regular maintenance - Industrial Coffee Grinder. Search for grinders that include self-cleaning devices or call for minimal disassembly, content as these features can conserve important labor hours

In addition, clear maintenance routines and documentation are crucial. Mills that feature extensive user handbooks detailing upkeep treatments can help operators comply with finest techniques, guaranteeing constant efficiency and top quality. By purchasing a commercial coffee mill that highlights ease of use and upkeep, organizations can improve efficiency, decrease operational prices, and keep the high requirements anticipated in coffee production.

Sound Level Reduction

When selecting a commercial coffee mill, noise level decrease is an essential element that can substantially affect the work click to investigate setting. High noise levels can bring about employee exhaustion, lowered focus, and potential hearing damage gradually, making it vital to pick a grinder developed with sound-dampening attributes.

Seek mills that include advanced noise-reduction technologies, such as sound-insulated housings and vibration-dampening places. These functions aid to minimize operational noises, developing a quieter ambience conducive to productivity. Industrial Coffee Grinder. In addition, picking grinders furnished with low-noise motors can further improve audio reduction, ensuring a more pleasurable workplace

Think about the grinder's total design, also. Models with incorporated sound-absorbing products can considerably decrease noise emissions during grinding cycles. The placement of the grinder within the office ought to be calculated. Positioning it on a steady, heavy surface area can aid to minimize vibrations that contribute to noise.

Ultimately, spending in a coffee grinder that prioritizes sound decrease not just improves the convenience of workers but also aligns with a dedication to keeping a safe and productive workplace. This attention to detail can cause improved worker complete satisfaction and retention.

Final Thought

In summary, choosing an industrial coffee mill necessitates cautious factor to consider of several essential attributes. Grind size consistency is important for ideal extraction, while flexible grinding speed facilitates an equilibrium between throughput and high quality.

Industrial coffee grinders are created to give a high level of precision, often employing burr grinding devices to make certain an uniform grind dimension. Unlike blade mills, which can produce a mix of fine and coarse bits, burr grinders crush the beans between 2 surfaces, permitting for better control over grind dimension. In recap, spending in a commercial coffee mill with an emphasis on work dimension uniformity is vital for accomplishing high-grade coffee with preferable flavor profiles.

Grinding rate plays a crucial role in the general performance of commercial coffee visit this web-site mills, directly influencing both the top quality of the grind and the effectiveness of the operation. A grinder that provides adjustable speed settings can provide optimal flexibility, enabling operators to tailor the grinding process according to specific demands.

Report this page